Guides and Tutorials

How to Shave a Cylinder Head on a Lathe

As a seasoned mechanic, I have always found the process of machining a cylinder head on a lathe to be both intriguing and demanding.

It’s like sculpting a masterpiece from a block of metal, carefully reshaping and refining it to achieve optimal performance.

In this comprehensive guide, I’ll walk you through the step-by-step process of understanding cylinder heads, preparing them for shaving, setting up on the lathe, and ultimately achieving a perfectly shaved surface.

So, grab your tools and let’s dive into the art of cylinder head shaving.

Key Takeaways

- Cylinder heads are important components of an internal combustion engine, sitting atop the engine block and containing various crucial elements.

- Common issues with cylinder heads include cracks, warping, and valve problems, which can affect engine performance.

- Safety precautions, such as wearing goggles and gloves, are necessary when working with cylinder heads on a lathe.

- Proper preparation, shaving, inspection, and finishing are essential steps in successfully shaving a cylinder head on a lathe.

Understanding Cylinder Heads

To understand cylinder heads, you’ll need to know their purpose and how they function within an engine.

Cylinder heads are crucial components of an internal combustion engine. They sit atop the engine block and contain the combustion chambers, intake and exhaust ports, and valve train components.

The purpose of the cylinder head is to seal the combustion chambers and provide a surface for the valves to open and close. It also plays a role in directing the flow of air and fuel into the combustion chamber and the exhaust gases out of it.

However, cylinder heads can develop issues over time, such as cracks, warping, or valve problems. These common cylinder head issues can affect engine performance and may require repair or replacement to ensure optimal functioning.

Tools and Equipment Needed

You’ll need a few specific tools and pieces of equipment for this task.

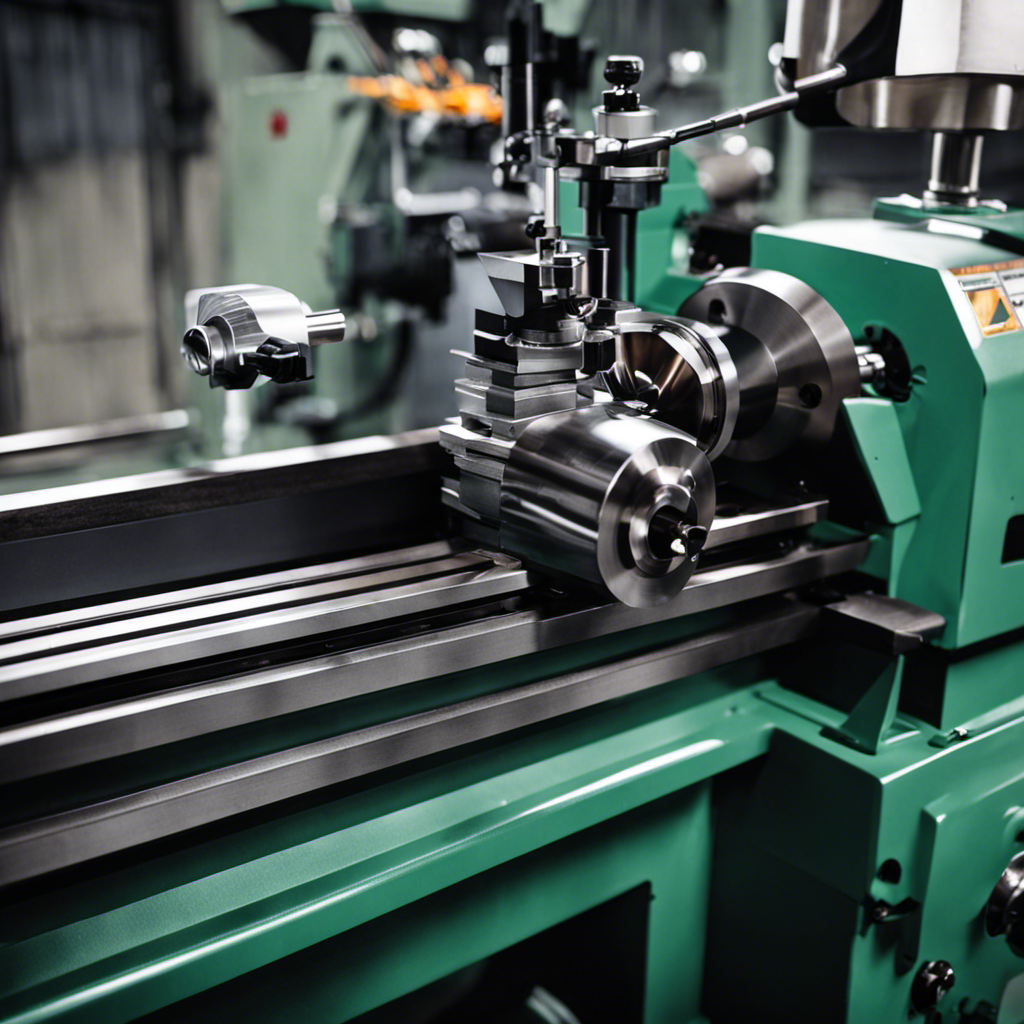

First and foremost, a lathe with a chuck and a cutting tool is essential. The chuck will securely hold the cylinder head in place, while the cutting tool will shave off any imperfections.

Additionally, safety precautions should not be overlooked. Safety goggles are a must to protect your eyes from any flying debris. It’s also important to wear gloves to prevent any accidental cuts or burns.

When it comes to cutting techniques, make sure to take small and precise cuts to achieve the desired results.

Once you have all the necessary tools and equipment, you can move on to preparing the cylinder head for shaving.

Preparing the Cylinder Head for Shaving

Before starting, make sure you have all the necessary safety gear, including goggles and gloves. Preparing the cylinder head for shaving requires a set of tools and safety precautions to ensure a smooth and successful process. Here is a table that outlines the tools needed for this task:

| Tools Needed | Purpose |

|---|---|

| Cylinder head gasket | Protects the cylinder head from leaks |

| Piston ring set | Ensures proper compression in the combustion chamber |

| Torque wrench | Tightens bolts to the recommended specifications |

| Feeler gauge | Measures the gap between components |

| Cylinder head bolts | Secures the cylinder head to the engine block |

It is important to follow safety precautions while preparing the tools. Always wear gloves and goggles to protect yourself from any potential injuries. Once the necessary tools are gathered and safety precautions are in place, you can move on to setting up the cylinder head on the lathe.

Setting Up the Cylinder Head on the Lathe

Once the safety precautions are in place, it’s time to position the cylinder head onto the lathe for further work. Before proceeding, it is crucial to ensure that the lathe is securely anchored and that all safety guards are in position.

To begin, I carefully position the cylinder head on the lathe’s spindle, making sure that it is aligned properly. Then, I employ clamping techniques to secure the cylinder head in place, preventing any movement during the shaving process. This is essential for achieving precise and accurate results.

I double-check the clamping to ensure it is tight enough to hold the cylinder head firmly, but not so tight as to cause any damage. Once everything is set up, I am ready to start the shaving process with confidence, knowing that I have taken the necessary lathe safety precautions.

Shaving the Cylinder Head

To achieve smooth and precise results, it’s important to carefully position the cylinder head on the lathe’s spindle. Once the cylinder head is securely in place, it’s time to begin the shaving process.

Shaving the cylinder head is an essential part of cylinder head maintenance, as it helps to ensure proper sealing and optimal performance of the engine. Here are three key shaving techniques to consider:

-

Depth of Cut: It’s crucial to determine the appropriate depth of cut for the cylinder head. This will depend on factors such as the condition of the head and the desired specifications. Taking too much material off can result in a loss of compression, while not shaving enough can lead to leaks.

-

Cutting Speed: The cutting speed should be carefully controlled to avoid overheating the cylinder head. This can cause warping or damage to the head. It’s important to find the right balance between speed and precision.

-

Tool Selection: Choosing the right cutting tool is vital for achieving accurate results. Different tools are designed for specific materials and cutting depths. It’s essential to select a tool that is suitable for the specific cylinder head material and shaving requirements.

Inspecting the Shaved Surface

Take a close look at the surface you’ve just shaved to ensure that it is smooth and free of any imperfections or uneven areas. Evaluating surface smoothness is crucial in determining the quality of the shaving process.

Start by running your fingers gently across the surface, feeling for any rough spots or irregularities. Next, visually inspect the surface under good lighting conditions. Look for any visible scratches, gouges, or unevenness. A smooth and uniform surface indicates a successful shaving operation.

Additionally, measuring the shaved thickness is another important step in evaluating the quality of the shave. Use a micrometer or a precision measuring tool to measure the thickness at multiple points on the surface. Compare these measurements to the desired specifications to ensure accuracy and consistency.

Finishing and Reinstalling the Cylinder Head

After ensuring a smooth and uniform surface, you can now finish and reinstall the cylinder head. To ensure a successful reinstallation, it is important to follow proper techniques. Here are some key points to keep in mind:

- Clean the cylinder head thoroughly before reinstalling. Any debris or contaminants can affect the performance and longevity of the engine.

- Apply a thin layer of high-quality gasket sealer on both sides of the head gasket. This will help create a tight seal and prevent any leaks.

- Use a torque wrench to tighten the head bolts to the manufacturer’s specifications. Over-tightening can lead to damage, while under-tightening can cause leaks.

Now let’s talk about some common shaving mistakes to avoid during the reinstallation process:

- Not properly aligning the head gasket with the cylinder head can result in coolant leaks and reduced engine performance.

- Failing to clean and inspect the head bolts can lead to improper torque and potential failure.

- Neglecting to properly torque the head bolts can cause cylinder head warping and engine damage.

Frequently Asked Questions

Can I Shave a Cylinder Head Using Hand Tools Instead of a Lathe?

I prefer using a lathe to shave a cylinder head, but alternative methods are possible. Using hand tools may be less precise and time-consuming. Pros include affordability, while cons include potential for uneven results and longer processing time.

How Long Does It Typically Take to Shave a Cylinder Head on a Lathe?

Shaving a cylinder head on a lathe can take varying amounts of time depending on factors like the condition of the head, the speed and accuracy of the lathe, and the skill of the operator.

Are There Any Specific Safety Precautions I Should Take While Shaving a Cylinder Head?

When shaving a cylinder head on a lathe, it is crucial to prioritize safety precautions. Ensure you have the necessary equipment, such as safety goggles and gloves, and follow proper procedures to prevent accidents.

Can I Reuse the Old Head Gasket After Shaving the Cylinder Head?

Reusing the old gasket after shaving the cylinder head is not recommended. It may not create a proper seal, causing leaks. Alternative methods include using a new gasket or having a professional reseal the head.

What Are the Signs That a Cylinder Head Needs to Be Shaved?

When determining if a cylinder head needs shaving, signs of damage such as warping, cracks, or excessive wear should be considered. It’s crucial to have a professional handle cylinder head shaving for precise results.

Conclusion

In conclusion, shaving a cylinder head on a lathe requires careful preparation and precise execution. By following the steps outlined in this article, you can achieve a smooth and flat surface on your cylinder head, ensuring optimal performance of your engine.

Interestingly, studies have shown that shaving a cylinder head can increase the compression ratio by up to 0.5, resulting in improved power and fuel efficiency. So, if you’re looking to enhance your engine’s performance, shaving the cylinder head is definitely worth considering.

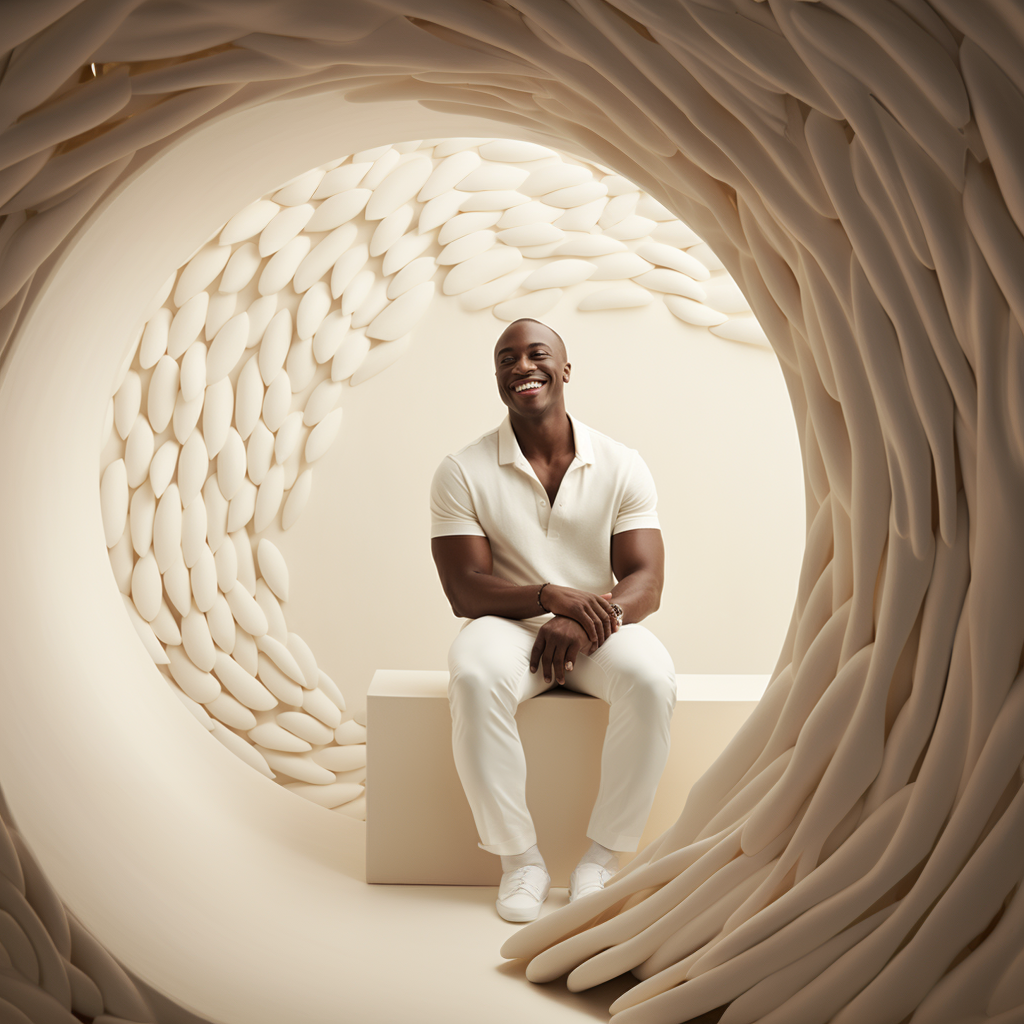

Atlas – Editor in Chief: The guiding force of Head Shave Products, Atlas steers the ship with a steady hand and a keen eye for detail. His vast experience in the shaving industry combined with his leadership skills makes him the linchpin of our operations. Beyond his professional duties, Atlas serves as a mentor, sharing his wisdom and insights with the rest of the team.

Guides and Tutorials

How Do Guys Shave Their Head

How can men like me achieve a smooth, hair-free look that offers an invigorating experience and boosts confidence?

In this article, I’ll guide you through the different methods, the right razor to choose, and how to prepare your scalp for the ultimate shave. We’ll tackle common challenges and explore alternative techniques, all while ensuring you maintain that sleek, bald head look.

So, get ready to embark on a journey to a perfectly shaved head!

Key Takeaways

- Electric razors and manual razors with a pivoting head are popular methods for shaving the head.

- Choosing the right razor with sharp blades and a comfortable handle grip is important for a smooth shave.

- Proper scalp preparation, including wetting the scalp with warm water and applying shaving cream or gel, is necessary for a smooth shave.

- Maintaining a bald head look involves hydrating the scalp, protecting it from UV rays, massaging the scalp, and preventing irritation and ingrown hairs.

Different Methods of Shaving the Head

There are various methods of shaving your head, depending on your personal preference and the desired outcome.

When it comes to alternative shaving techniques, one popular method is using an electric razor. This allows for a quick and convenient shave, with the added benefit of preventing razor burn. Electric razors are designed to cut the hair close to the scalp without causing irritation.

Another alternative technique is using a manual razor with a pivoting head. This allows for better control and smooth gliding over the contours of the head.

To prevent razor burn, it is important to prepare the skin properly by washing it with warm water and using a shaving cream or gel. Additionally, shaving in the direction of hair growth and using short, gentle strokes can help minimize irritation.

Choosing the Right Razor for a Smooth Shave

When it comes to choosing the right razor for a smooth shave, it’s important to consider factors like blade sharpness and handle grip. Here are three key factors to consider when selecting a razor that will prevent irritation and ingrown hairs:

-

Blade sharpness: Look for razors with sharp blades that can easily glide through the hair without tugging or pulling. Dull blades can cause friction and irritation on the scalp, leading to discomfort and potential ingrown hairs.

-

Handle grip: A razor with a comfortable and secure handle grip is crucial for a smooth shaving experience. It allows for better control and reduces the risk of accidental cuts or nicks.

-

Blade replacement: Opt for razors with easily replaceable blades. Regularly changing the blade ensures a sharp and clean shave, minimizing the chances of irritation and ingrown hairs.

By carefully considering these factors, you can choose a razor that will provide a smooth and irritation-free shave.

Now, let’s move on to preparing the scalp for shaving.

Preparing the Scalp for Shaving

Before starting the shave, it’s important to properly prepare the scalp for a smooth shaving experience. Taking care of your scalp not only ensures a comfortable shave but also promotes overall scalp health.

Here are some tips for scalp care before shaving.

First, wet your scalp with warm water to soften the hair and open up the pores.

Next, apply a moisturizing shaving cream or gel to create a smooth surface and prevent irritation.

Using a sharp razor, shave in the direction of hair growth to minimize the risk of ingrown hairs.

Lastly, rinse off any remaining shaving cream and pat your scalp dry.

Shaving the head has several benefits, including a clean and polished look, reduced maintenance, and the option to experiment with different hairstyles.

Step-By-Step Guide to Shaving the Head

To start shaving your head, begin by wetting your scalp with warm water to soften the hair and open up the pores. This step is crucial as it helps to prevent irritation and allows for a smoother shave.

Once your scalp is wet, you can choose the right technique that suits you best. Here are three options to consider:

-

Traditional Razor: This classic method involves using a sharp razor blade to remove the hair. It gives you a close shave and allows for precise control, but requires more time and effort.

-

Electric Shaver: This convenient option is quick and easy. It cuts the hair using oscillating blades or rotary heads. It’s ideal for those who prefer a low-maintenance approach and want to save time.

-

Clippers: Clippers are often used to trim hair, but they can also be used to shave the head. They offer a versatile option that allows you to adjust the length of the hair, giving you a customized look.

Shaving your head has several benefits, including a clean and polished appearance, reduced maintenance, and the ability to rock a bold style. So, choose the technique that suits you best and enjoy the benefits of a shaved head.

Dealing With Common Shaving Challenges

One of the most common challenges I face when shaving my head is razor burn, which can cause redness and irritation. To deal with razor bumps, I make sure to prepare my scalp properly before shaving.

First, I cleanse my head with a gentle exfoliating scrub to remove dead skin cells and unclog pores. This helps to prevent ingrown hairs and reduce the chances of razor bumps. Then, I apply a pre-shave oil to soften the hair and provide a smooth surface for the razor.

When it comes to preventing nicks and cuts, I always use a sharp blade and shave in the direction of hair growth. I also use a moisturizing shaving cream to create a barrier between the razor and my skin, reducing the risk of cuts.

Overall, following these steps helps me achieve a clean and smooth shave without any irritation or discomfort.

Maintaining a Bald Head Look

When maintaining a bald head look, it’s important to regularly moisturize the scalp to prevent dryness. Here are three essential tips for head shaving maintenance and bald head care:

-

Hydrate: Keeping the scalp hydrated is crucial to maintain a healthy bald head. Use a moisturizing shampoo specifically designed for bald heads to nourish and hydrate the scalp. This will help prevent dryness and flakiness.

-

Protect: Shield your scalp from harmful UV rays by wearing a hat or applying sunscreen. Exposing your bald head to the sun can cause sunburn and damage the skin. Choose a broad-spectrum sunscreen with SPF 30 or higher and apply it generously before heading outside.

-

Massage: Regularly massaging your scalp improves blood circulation, which promotes healthier hair growth. Use your fingertips to gently massage your scalp in circular motions for a few minutes each day. This not only feels relaxing but also helps distribute natural oils and maintain a balanced scalp.

Tips for Preventing Irritation and Ingrown Hairs

When it comes to shaving my head, I often find myself debating between using a razor or an electric shaver. Both have their pros and cons, so it’s important to consider factors such as skin sensitivity and desired level of closeness.

Additionally, I’ve learned that moisturizing after shaving is essential to keep my scalp hydrated and prevent irritation.

Razor or Electric

Guys often debate whether to use a razor or an electric device to shave their head. It’s a decision that can greatly impact the shaving experience and the end result. Here are the pros and cons of each option:

-

Razor:

- Pros: A razor provides a close, smooth shave that can last longer. It allows for precise control, especially when shaping facial hair or creating sharp lines. Plus, with the right technique, it can exfoliate the skin, leaving it feeling soft and refreshed.

- Cons: Shaving with a razor can be time-consuming, especially if you’re new to it. It requires careful handling to avoid cuts and nicks. Also, razor blades need to be replaced regularly, which can be an added expense.

-

Electric:

- Pros: An electric shaver offers convenience and speed. It requires minimal preparation, making it ideal for those with a busy lifestyle. It’s also generally safer, reducing the risk of cuts and irritation.

- Cons: Though electric shavers have improved over the years, they may not provide as close a shave as a razor. They can also be more expensive upfront. Additionally, some people find that electric shavers are louder and can cause more skin irritation.

Ultimately, the choice between a razor and an electric shaver comes down to personal preference and individual needs. It’s important to consider factors like skin sensitivity, desired shaving closeness, and time constraints.

Whichever option you choose, don’t forget to moisturize after shaving to soothe and hydrate your skin.

Moisturize After Shaving

After shaving your head, it’s important to moisturize the skin to keep it healthy and hydrated. Moisturizing can provide several benefits for your scalp and overall shaving experience. Not only does it help to prevent dryness and irritation, but it can also soothe any razor burn or redness that may occur.

To ensure your scalp stays moisturized, it’s recommended to use a moisturizer specifically designed for the head. These moisturizers are usually lightweight and non-greasy, allowing for quick absorption without leaving a residue. They often contain ingredients like aloe vera or chamomile, which have soothing properties.

Here are some head shaving tips for moisturizing:

| Tip | Description |

|---|---|

| 1. Choose the right moisturizer | Look for a moisturizer specifically designed for the head that suits your skin type. |

| 2. Apply after shaving | Gently apply the moisturizer to your freshly shaved scalp to lock in moisture. |

| 3. Use daily | Make moisturizing a part of your daily routine to maintain hydration and prevent dryness. |

Exploring Alternative Shaving Techniques for the Head

There are several different methods that can be used to shave your head. When it comes to alternative shaving techniques, it’s important to find the one that works best for you. Here are three options to consider:

-

Electric Shavers: These devices are convenient and offer a quick and efficient shave. They are especially helpful for those with sensitive skin or prone to irritation.

-

Wet Shaving with a Safety Razor: Although it requires more time and precision, wet shaving with a safety razor provides a close and smooth shave. It may take some practice to master the technique, but the results are worth it.

-

Head Blade: Designed specifically for head shaving, the Head Blade is a unique tool that offers excellent control and maneuverability. It simplifies the process and minimizes the risk of cuts or nicks.

Exploring alternative shaving techniques can help overcome head shaving challenges and ensure a comfortable and effective experience. Now, let’s address some frequently asked questions about head shaving.

Frequently Asked Questions About Head Shaving

When it comes to head shaving, finding the best technique is essential for achieving a smooth and clean look. In this discussion, I will explore the most effective head shaving techniques that have been recommended by experts and experienced individuals.

Additionally, I will provide a comprehensive list of recommended head shaving products that can help you achieve the best results and maintain a well-groomed appearance.

Best Head Shaving Techniques

One of the best head shaving techniques is to use a shaving cream or gel to help moisturize the scalp before shaving. This step is crucial for a smooth and comfortable shave.

Here are three reasons why this technique is beneficial:

-

Enhanced Comfort: Applying a shaving cream or gel creates a protective barrier between the razor and your scalp, reducing the risk of irritation and razor burn.

-

Hydration: Shaving cream or gel helps to lock in moisture, preventing dryness and flakiness on your bald head.

-

Improved Glide: The lubricating properties of shaving cream or gel allow the razor to glide effortlessly across the scalp, ensuring a close and precise shave.

Whether you prefer a razor or an electric shaver, using a shaving cream or gel beforehand will maximize the benefits of a bald head, leaving you with a smooth and polished look.

Recommended Head Shaving Products

Using a shaving cream or gel before shaving your head is essential for a smooth and comfortable experience. When it comes to bald head care, finding the right head shaving cream is crucial. Look for a cream specifically designed for head shaving, as it will provide the necessary lubrication and protection for your scalp.

These creams are often formulated with ingredients like aloe vera or vitamin E to soothe and moisturize your skin. Applying the cream evenly onto your head will create a barrier between the razor and your skin, reducing the risk of irritation or razor burn. Additionally, the cream will help soften your hair, making it easier to shave.

Frequently Asked Questions

How Long Does It Typically Take for Hair to Grow Back After Shaving the Head?

It typically takes a few weeks for hair to start growing back after shaving my head. To promote hair regrowth, I make sure to maintain a healthy diet, stay hydrated, and avoid excessive heat styling.

Is It Necessary to Use Shaving Cream or Gel When Shaving the Head?

When shaving my head, I find that using shaving cream or gel is not necessary. However, it can provide a smoother shave and minimize irritation. Some alternative products like hair conditioner or coconut oil can also work well.

Can Shaving the Head Cause Any Scalp or Skin Problems?

Shaving the head can sometimes lead to scalp or skin problems, such as irritation or ingrown hairs. However, practicing good scalp hygiene and using proper techniques, like exfoliating and moisturizing, can help prevent these issues and even stimulate hair growth.

Are There Any Specific Hair Care Products Recommended for Maintaining a Bald Head Look?

When it comes to maintaining a bald head look, using specific hair care products can be beneficial. These products are designed to keep the scalp moisturized and healthy, ensuring a smooth and polished appearance.

What Are Some Common Mistakes to Avoid When Shaving the Head for the First Time?

When shaving my head for the first time, I made some common mistakes. But with these tips for a smooth head shave, I learned to avoid them and achieve a polished look.

Conclusion

In conclusion, shaving your head can be a liberating experience. It allows you to embrace a bald head look and maintain a smooth and polished appearance.

By following the step-by-step guide and choosing the right razor, you can achieve a close shave without any irritation or ingrown hairs. Remember to properly prepare your scalp and address any common shaving challenges.

Whether you opt for traditional methods or explore alternative techniques, maintaining a bald head has never been easier.

So seize the opportunity to showcase your sleek and stylish self!

Lucy, with her knack for weaving words into compelling narratives, is a cherished member of our content team. Her journey into the world of content creation began with a love for storytelling, nurtured during evenings spent around campfires and family gatherings. These tales, filled with emotion and life lessons, left an indelible mark on her young mind, propelling her into the realm of writing.

Guides and Tutorials

How to Give Someone a Wet Shave to a Head

Are you interested in mastering the art of giving someone a wet shave for their head? You’re in luck because you’ve come to the right place.

In this article, I’ll guide you through the step-by-step process of achieving a smooth and comfortable shave that will leave your recipient feeling refreshed and confident.

From preparing the scalp to choosing the right tools and products, I’ll provide you with all the knowledge and techniques you need to become a shaving pro.

So, let’s dive in and unlock the secrets to a flawless wet shave for the head.

Key Takeaways

- Properly cleanse the scalp and exfoliate to prepare for a wet shave.

- Choose the right shaving tools and products for a personalized and comfortable experience.

- Use shaving creams and pre-shave oils to moisturize, protect, and soften the skin.

- Master the lathering technique and razor angle for effective hair removal without irritation.

Preparing the Scalp for a Wet Shave

Before starting the wet shave, it’s important to properly cleanse and exfoliate the scalp. Head preparation is crucial for a smooth and comfortable shave.

To begin, I recommend using a gentle cleanser to remove any dirt, oil, or product buildup from the scalp. This will ensure a clean surface for the razor to glide smoothly.

Next, exfoliation is key to remove dead skin cells and unclog the hair follicles. You can use a scalp scrub or a soft brush to gently massage the scalp in circular motions. This will promote blood circulation and help prevent ingrown hairs.

Remember to rinse thoroughly and pat dry before proceeding with the wet shave. Taking the time to care for the scalp before shaving will result in a more effective and enjoyable experience.

Choosing the Right Shaving Tools and Products

When it comes to achieving a smooth and comfortable shave, choosing the right shaving tools and products is essential.

Understanding the different types and features of razors allows for a personalized shaving experience that suits your needs and preferences.

Additionally, selecting the best shaving creams and incorporating pre-shave oils into your routine can enhance the overall quality of your shave by providing added lubrication and moisturization to the skin.

Razor Types and Features

There are different razor types and features to consider when giving someone a wet shave to their head. It is important to choose the right razor for the job to ensure a close and comfortable shave. Here are four key factors to consider:

-

Razor Blade Sharpness: The sharpness of the razor blade is crucial for achieving a smooth and precise shave. Dull blades can cause irritation and uneven cuts. Regularly check the sharpness of the blades and replace them as needed.

-

Number of Blades: Razors with multiple blades offer a closer shave as they can cut through more hair in one stroke. Look for razors with three or more blades for a smoother result.

-

Ergonomic Design: A razor with an ergonomic design ensures a comfortable grip and better control during the shaving process. Look for a razor with a non-slip handle and a balanced weight for easy maneuvering.

-

Easy Razor Maintenance: Choose a razor that is easy to clean and maintain. Some razors come with detachable heads or cartridges that can be easily replaced, making it convenient to keep the razor in good condition.

Best Shaving Creams

To achieve a smooth and comfortable shave, you should consider using the best shaving cream available. The right shaving cream can make a world of difference in your shaving experience. Not only does it provide lubrication and protection for your skin, but it also helps to soften your facial hair, making it easier to cut.

When choosing a shaving cream, it’s important to look for ingredients that are gentle on your skin and help to moisturize and nourish it. Some common ingredients found in high-quality shaving creams include aloe vera, shea butter, and coconut oil. These ingredients work together to hydrate your skin and prevent irritation.

Additionally, it’s important to learn proper shaving cream application techniques to ensure a close and comfortable shave. Here are some tips for applying shaving cream effectively:

- Wet your face with warm water to open up your pores and soften your facial hair.

- Dispense a small amount of shaving cream onto your fingertips or a shaving brush.

- Gently massage the shaving cream onto your face in circular motions, making sure to cover all areas that you plan to shave.

- Allow the shaving cream to sit on your face for a minute or two to further soften your facial hair.

- Begin shaving using a sharp razor, following the direction of hair growth and rinsing the blade frequently.

Pre-Shave Oils Benefits

For a more nourishing and moisturizing shaving experience, consider using pre-shave oils before applying your shaving cream. Pre-shave oils offer several benefits that can greatly enhance your shaving routine. Here are four reasons why you should incorporate pre-shave oils into your grooming regimen:

-

Exfoliating: Pre-shave oils help to exfoliate the skin, removing dead skin cells and unclogging pores. This leads to a smoother shave and reduces the chances of ingrown hairs.

-

Moisturizing: The oils in pre-shave oils deeply moisturize the skin, leaving it soft and supple. This helps to prevent dryness and irritation during and after shaving.

-

Lubrication: Pre-shave oils create a slick surface on the skin, allowing the razor to glide effortlessly. This minimizes friction and reduces the risk of nicks and cuts.

-

Reducing Irritation: The nourishing properties of pre-shave oils help to soothe and calm the skin, reducing redness and irritation caused by shaving.

Step-By-Step Guide to Lathering the Head

Once you’ve prepared the head for shaving, start by applying a generous amount of shaving cream to the scalp.

Lathering techniques are crucial in achieving a smooth and irritation-free shave. Begin by wetting your hands with warm water, then take a dollop of shaving cream and rub it between your palms to create a rich lather.

Gently massage the lather onto the scalp using circular motions, making sure to cover the entire shaved area. This helps to lift the hairs, making them easier to cut and reducing the risk of razor burn.

Take your time to evenly distribute the lather, ensuring that each hair is coated. Remember to reapply more shaving cream if needed to maintain a good lather throughout the shave.

Mastering the Art of Razor Technique

When it comes to achieving a close and comfortable shave, mastering the art of razor technique is crucial.

One key aspect is maintaining the proper razor angle to ensure effective hair removal without causing irritation.

Additionally, shaving against the grain can provide an even closer shave, but it requires caution and technique to prevent skin irritation.

Lastly, moisturizing post-shave is essential for soothing the skin, minimizing razor burn, and promoting overall skin health.

Proper Razor Angle

To achieve a proper razor angle, you need to hold the razor at a 30-degree angle to the skin. This is crucial for a close and comfortable shave while minimizing the risk of nicks and cuts. Here are some key points to keep in mind when it comes to maintaining the razor angle and preventing razor burn:

-

Inspect the razor: Regularly check the razor blade for any signs of rust, dullness, or damage. Replace the blade as needed to ensure a sharp and clean shave.

-

Prepare the skin: Before shaving, cleanse the skin with warm water to soften the hair and open up the pores. This will make it easier for the razor to glide smoothly over the skin.

-

Use light pressure: Apply gentle pressure to the razor, allowing the weight of the razor to do most of the work. Avoid pressing too hard, as this can lead to irritation and razor burn.

-

Shave in the direction of hair growth: Always shave in the direction of hair growth to minimize the risk of ingrown hairs and irritation. This will also help achieve a closer shave without causing unnecessary friction.

By following these razor maintenance tips and paying attention to the razor angle, you can prevent razor burn and achieve a smooth and comfortable shave.

Now, let’s move on to the next step: shaving against the grain.

Shaving Against Grain

For a closer shave, remember to apply light pressure when shaving against the grain to avoid irritation and ingrown hairs. Shaving against the grain can provide a smoother result, but it also increases the risk of razor bumps and skin irritation.

To minimize these issues, it is important to follow proper shaving techniques and take preventive measures. Here are some tips to help you achieve a smooth shave while preventing razor bumps:

-

Use a sharp blade: A dull blade can cause more friction and increase the chances of irritation. Replace your blade regularly to ensure a clean and sharp shave.

-

Prep your skin: Before shaving, cleanse your skin with warm water and a gentle cleanser to remove any dirt or oils. This will soften the hair and make it easier to shave.

-

Moisturize: After shaving, apply a soothing moisturizer to hydrate your skin and reduce any post-shave irritation.

Moisturizing Post-Shave

Applying a soothing moisturizer after shaving helps to hydrate the skin and reduce post-shave irritation. Moisturizing techniques play a crucial role in preventing razor burn and maintaining a healthy complexion. Here are four essential tips for effective post-shave moisturizing:

-

Choose the right moisturizer: Look for a product specifically formulated for post-shave use. It should be lightweight, non-greasy, and contain ingredients like aloe vera or chamomile to soothe and calm the skin.

-

Apply immediately: After shaving, pat the skin dry with a clean towel and apply the moisturizer while the skin is still slightly damp. This helps to lock in moisture and enhance absorption.

-

Use gentle, upward strokes: Massage the moisturizer into the skin using gentle upward movements. This promotes blood circulation and aids in the absorption of the product.

-

Don’t forget the neck: Extend the moisturizer application to the neck area, as it is often prone to irritation and razor burn. Ensure thorough coverage for a well-moisturized and smooth finish.

Navigating Tricky Areas on the Head

When shaving your head, it can be challenging to navigate tricky areas like the back of your head and behind the ears. These areas are prone to nicks and cuts, as well as razor burn if not handled properly. To avoid these issues, it is important to approach these areas with caution and precision.

When shaving the back of your head, use a handheld mirror or ask for assistance to ensure you can see what you’re doing.

For the areas behind the ears, gently pull the earlobe to make the skin taut and shave carefully, using short, controlled strokes.

Tips for a Smooth and Comfortable Shave

To achieve a smooth and comfortable shave, it’s important to approach tricky areas with caution and precision. Here are some tips to help prevent razor burn and reduce ingrown hairs:

-

Prepare your skin: Before shaving, make sure to cleanse your skin with a gentle cleanser to remove any dirt or oils. This will help soften the hair and open up the pores, making it easier to get a close shave.

-

Use a sharp razor: Using a dull razor can increase the risk of razor burn and ingrown hairs. Make sure to use a sharp razor and replace the blades regularly to ensure a clean and smooth shave.

-

Shave with the grain: Shaving against the direction of hair growth can cause irritation and ingrown hairs. Instead, shave in the direction that the hair naturally grows to reduce the risk of razor burn and ingrown hairs.

-

Moisturize after shaving: After you’ve finished shaving, apply a moisturizer or aftershave lotion to soothe the skin and keep it hydrated. This will help prevent razor burn and promote healthy skin.

Aftercare for a Freshly Shaved Head

Take a few minutes to gently massage a moisturizing lotion into your freshly shaved scalp to keep it hydrated and prevent any dryness or irritation. After a wet shave, your scalp may feel sensitive and in need of some extra care. A scalp care routine is essential to maintain its health and appearance. Here is a simple three-step routine that you can follow:

| Step | Action | Product |

|---|---|---|

| 1 | Clean | Use a gentle cleanser specifically designed for the scalp to remove any dirt or excess oil. |

| 2 | Moisturize | Apply a moisturizing lotion or oil to nourish and hydrate the scalp. Look for products that contain ingredients like aloe vera or shea butter. |

| 3 | Protect | After moisturizing, don’t forget to apply sunscreen to your freshly shaved head to protect it from harmful UV rays. Choose a broad-spectrum sunscreen with at least SPF 30. |

Following this scalp care routine will help keep your freshly shaved head healthy, hydrated, and protected from the sun.

Troubleshooting Common Shaving Problems

If you experience any common shaving problems, such as razor burn or ingrown hairs, there are a few simple solutions you can try. Here are four effective ways to troubleshoot razor burn and prevent ingrown hairs:

-

Use a sharp razor blade: Dull blades can cause irritation and increase the likelihood of razor burn. Replace your blade regularly to ensure a clean and smooth shave.

-

Prep your skin properly: Before shaving, make sure to cleanse your skin and soften the hair with warm water. This will help minimize irritation and make the shaving process easier.

-

Apply a shaving cream or gel: Using a high-quality shaving cream or gel creates a protective barrier between the razor and your skin. This reduces friction and helps prevent razor burn.

-

Follow the grain: Shave in the direction of hair growth to prevent ingrown hairs. Going against the grain can cause the hair to curl back into the skin, leading to painful ingrown hairs.

Frequently Asked Questions

How Long Does It Take for Hair to Grow Back After a Wet Shave?

Hair growth after a wet shave varies, but typically it takes about 1-2 weeks to see noticeable regrowth. To promote faster hair growth, try moisturizing the scalp, eating a balanced diet, and avoiding excessive heat styling.

Can I Use Regular Shaving Cream or Do I Need a Specific Product for a Wet Shave?

I prefer using a specific product for wet shaving on the head because it provides better lubrication and protection against irritation. Alternatives like shaving cream can work, but they may not offer the same level of comfort and effectiveness.

Is It Necessary to Exfoliate the Scalp Before a Wet Shave?

Exfoliating the scalp before a wet shave is not necessary, but it can be beneficial. It helps remove dead skin cells, allowing for a smoother shave. Using a pre-shave oil can also provide added protection and lubrication for a comfortable shave.

Are There Any Specific Techniques to Prevent Razor Bumps or Ingrown Hairs on the Head?

To prevent razor bumps and ingrown hairs on the head, it’s crucial to follow best practices and aftercare tips. By using proper shaving techniques, moisturizing the skin, and regularly exfoliating, you can minimize these issues.

Can I Use an Electric Razor for a Wet Shave on the Head?

Yes, you can use an electric razor for a wet shave on the head. Electric razors have the advantage of being quick and convenient. However, a wet shave with a manual razor provides a closer and smoother shave.

Conclusion

Well, there you have it, folks. The ultimate guide to giving someone a wet shave to the head. Armed with the right tools, techniques, and a little bit of patience, you can transform any noggin into a smooth and shiny masterpiece.

Just remember to lather up, master the art of razor technique, and navigate those tricky areas with finesse.

And if all else fails, don’t worry, we’ve got some troubleshooting tips for you too.

So go forth and shave with confidence, my friends. Your head will thank you.

Lucy, with her knack for weaving words into compelling narratives, is a cherished member of our content team. Her journey into the world of content creation began with a love for storytelling, nurtured during evenings spent around campfires and family gatherings. These tales, filled with emotion and life lessons, left an indelible mark on her young mind, propelling her into the realm of writing.

Guides and Tutorials

Howie Mandel Why Did He Shave His Head

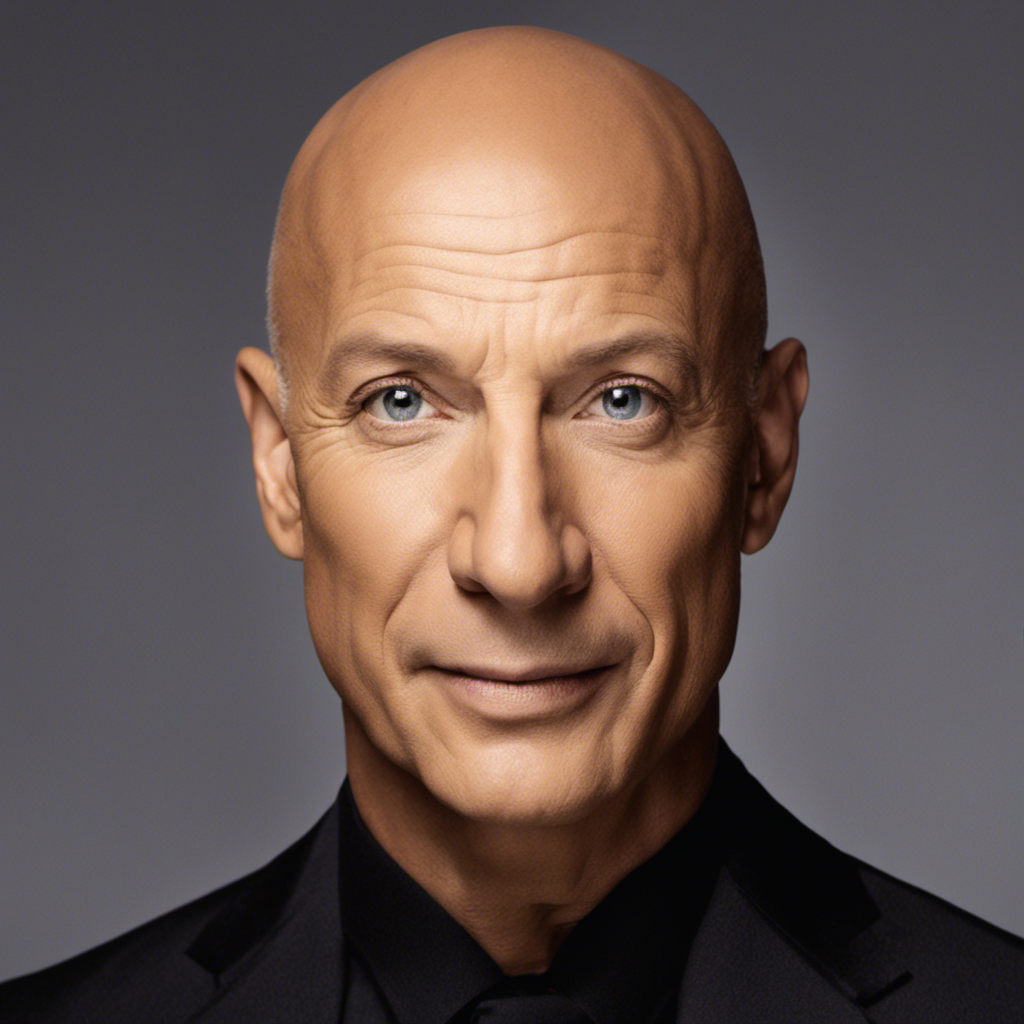

Curious about why Howie Mandel decided to shave his head? Let me give you the inside story.

The iconic comedian and TV personality recently made a daring move, shaving off his luscious locks. But what made him take the plunge?

In this article, we’ll delve into the fascinating journey of Howie’s new look and explore the reasons behind his decision. From hair loss concerns to personal style evolution, we’ll uncover the truth behind this buzzworthy transformation.

Get ready, because it’s time to uncover the secrets behind Howie Mandel’s shiny new dome.

Key Takeaways

- Howie Mandel embraced the bald look to stay in line with Hollywood trends and to assert his individuality.

- His decision to go bald showcases his willingness to embrace change and challenges societal beauty standards.

- Going bald can be both stylish and practical, especially for those seeking a low-maintenance hairstyle.

- Howie Mandel’s decision to shave his head has received overwhelming support and positive reception from the public.

The Decision to Shave

Why did Howie Mandel decide to shave his head?

The bald look is all the rage in Hollywood, and it seems like Howie didn’t want to be left behind. The beloved comedian and television host recently made the bold decision to embrace change and go for a completely bald look.

But what prompted this dramatic transformation? Rumors have been swirling that Howie wanted a fresh start, a new image that would set him apart from the crowd. Some say he was tired of the constant maintenance of his signature hairstyle, while others speculate that it was a personal decision, a way for him to assert his individuality.

Whatever the reason, Howie Mandel is rocking the bald look like a true trendsetter, proving once again that change can be a beautiful thing.

Howie’s New Look

Oh, the buzz around Howie Mandel’s new look is sending shockwaves through Hollywood! The beloved comedian and TV personality has ditched his signature hairdo and gone completely bald.

But is this a bold fashion statement or a practical choice? Let’s dive into the juicy details and explore whether Howie’s new look is a stylish triumph or a practical makeover.

Bald or Bold

You should embrace your baldness like Howie Mandel did – it’s a bold and confident look!

In a world obsessed with luscious locks and flowing manes, it’s refreshing to see someone break free from the societal beauty standards. Howie, known for his quick wit and infectious laughter, decided to ditch the hair and embrace his baldness. And let me tell you, he looks better than ever!

Gone are the days of hiding under caps or struggling with hair loss treatments. Howie’s decision to embrace his baldness has challenged the stigma of baldness and shown us that true confidence comes from within.

Stylish or Practical?

If you’re looking for a low-maintenance hairstyle, going bald can be both stylish and practical. Just ask the legendary Howie Mandel, who recently made headlines when he shaved off his signature locks. But what led this funnyman to take the plunge? Rumor has it that Mandel was tired of dealing with the hassle of styling his thinning hair. And who can blame him?

In a world obsessed with perfect coifs and luscious locks, societal expectations can be tough to meet. But Mandel’s decision to embrace his baldness is a lesson in self-confidence and authenticity. For those facing hair loss, there are various solutions available, from hair transplants to stylish wigs.

Hair Loss Concerns

Are you starting to notice a few more strands in the shower drain? Don’t panic, because I’ve got the inside scoop on coping with baldness and the latest hair loss treatment options.

From Hollywood heartthrobs to everyday folks, hair loss is a universal concern that can really knock our confidence. But fear not, because I’ve got the lowdown on how to embrace your new look or explore the exciting world of hair restoration.

Coping With Baldness

Don’t worry, there are many ways to cope with baldness. Whether you’re a Hollywood heartthrob or an everyday Joe, baldness acceptance and self-esteem impact everyone. Just ask Howie Mandel, the famous comedian and TV host known for his clean-shaven head. Rumor has it that Howie decided to embrace his baldness after years of battling hair loss. And let me tell you, he’s never looked better! But Howie is not alone in his journey. Many other celebrities and regular folks have also found ways to cope with their thinning locks. Check out this handy table for some inspiration:

| Celebrity | Coping Method |

|---|---|

| Dwayne Johnson | Rocking the bald look |

| Jason Statham | Sporting a buzz cut |

| Patrick Stewart | Embracing the chrome dome |

| Vin Diesel | Going completely bald |

Hair Loss Treatment Options

Looking to address hair loss? Don’t worry, I’ve got the inside scoop on how to combat that receding hairline or thinning crown. There are several treatment options available to you. Check out these four hair loss treatment options that are making waves in Hollywood:

-

Hair loss prevention: Stop the shedding before it even starts! From specialized shampoos to vitamin supplements, there are plenty of products on the market claiming to prevent hair loss. Keep your locks luscious with these preventative measures.

-

Hair transplant surgery: If your hairline has already done a disappearing act, fear not! Celebrities like Wayne Rooney and Elon Musk have turned to hair transplant surgery to restore their former glory. This surgical procedure involves taking hair follicles from one area of the body and transplanting them to the balding areas. Voila, a full head of hair!

-

PRP therapy: Platelet-Rich Plasma therapy is gaining popularity among the A-listers. This non-surgical treatment stimulates hair growth by injecting your own plasma into the scalp. It’s like giving your hair a shot of youth!

-

Laser therapy: Zap away hair loss with the power of lasers! Low-level laser therapy has been shown to stimulate hair follicles and promote regrowth. It’s a painless and convenient option for those looking to turn back the clock on their thinning tresses.

Personal Style Evolution

You may wonder why Howie Mandel decided to shave his head and how it reflects his personal style evolution. Well, let me tell you, it’s all about staying ahead of the game in the ever-changing world of celebrity trends. Howie, known for his iconic bald look, has embraced his hair transformation as a way to showcase his bold and confident style.

To better understand the impact of his decision, let’s take a look at this table:

| Before | During | After |

|---|---|---|

| Wild curls | Receding hairline | Clean-shaven |

Before, Howie rocked wild curls that were full of personality. But as time went on, he noticed his hairline receding. Instead of fighting it, he made the daring choice to shave it all off. And boy, did it pay off! The clean-shaven look suits him perfectly and has become his signature style.

The Influence of COVID-19

The influence of COVID-19 has led to significant changes in the world of celebrity trends. From the red carpet to the streets, our favorite stars are adapting to the ‘new normal’ and embracing a more casual and relatable style. Here’s how the pandemic has affected celebrity fashion:

-

Comfort is king: Gone are the days of sky-high heels and restrictive outfits. Celebrities are opting for cozy loungewear and athleisure, prioritizing comfort over glamour.

-

Virtual fashion shows: With traditional fashion shows on hold, designers are turning to digital platforms to showcase their collections. Celebrities are attending these virtual events, setting trends with their Zoom-worthy ensembles.

-

DIY fashion: With more time at home, celebrities are exploring their creative sides and experimenting with DIY fashion. From tie-dye to embroidery, they’re customizing their clothes and making fashion statements from the comfort of their living rooms.

-

Embracing imperfections: The pandemic has sparked conversations about insecurity issues and societal expectations. Celebrities are using their platforms to promote body positivity and self-acceptance, encouraging fans to embrace their flaws and celebrate their uniqueness.

In this ever-changing world, celebrities are showing us that fashion is not just about looking good, but also about feeling good and staying true to oneself. So, let’s raise a glass to the stars who are using their influence for good and inspiring us to embrace our own personal style, imperfections and all.

Confidence Boost

Feeling confident in your own skin is key to embracing your personal style, imperfections and all.

And when it comes to personal transformation, there’s no better example than Howie Mandel’s recent decision to shave his head. The iconic comedian and TV personality, known for his signature curly hair, made the bold move to embrace a new look.

But it wasn’t just about a change in appearance; it was a statement of self-esteem. Mandel’s decision to go bald was a testament to his confidence and willingness to embrace his true self. In a world where society often dictates beauty standards, his move was a powerful reminder that true beauty comes from within.

It’s a lesson we can all learn from, as we navigate our own personal journeys and strive to embrace our authentic selves.

Public Reaction and Support

Witnessing the public’s overwhelming support for his new bald look must have been incredibly uplifting for Howie Mandel. After shaving his signature hair on a whim, the comedian took the internet by storm. Public opinion erupted, and social media platforms were flooded with reactions to his daring new style.

Here are four key highlights from the social media response:

-

The Bald Brotherhood: Fans praised Mandel’s decision, hailing him as a brave member of the Bald Brotherhood. They admired his confidence and saw it as a symbol of self-acceptance.

-

Memes Galore: Social media exploded with hilarious memes featuring Mandel’s bald head. From photoshopped images to clever captions, the internet had a field day, showcasing its creativity and wit.

-

Fashion Forward: Many applauded Mandel’s bald look for being edgy and stylish. They saw it as a fashion statement, proving that confidence can be the best accessory.

-

Supportive Messages: Fans and celebrities alike flooded Mandel’s social media accounts with supportive messages. They praised his courage and sent love, reminding him that he is not alone in his hairless journey.

The public’s overwhelming support and positive reception have undoubtedly boosted Mandel’s spirits, showing that sometimes, a simple change can have a profound impact.

Frequently Asked Questions

Does Howie Mandel’s Decision to Shave His Head Have Any Connection to His Career or Upcoming Projects?

Howie Mandel’s bald look has sparked curiosity among fans. The public reaction to his shaved head ranges from admiration for his bold style to speculation about upcoming projects. Let’s dig into the buzz!

How Long Did It Take for Howie to Adjust to His New Bald Look?

It took me some time to fully embrace my new bald look, but now I’m rocking it with confidence! Fans are loving the trend, and I’m enjoying this journey of self-acceptance.

Did Howie Consult With Any Experts or Professionals Before Deciding to Shave His Head?

Before deciding to shave his head, Howie Mandel did extensive research and consulted with hair care experts. He wanted to make sure he was making the right decision for his look and personal style.

Has Howie Mandel Ever Experienced Hair Loss in the Past?

Yes, Howie Mandel has experienced hair loss in the past, which led to his decision to shave his head. While there are various causes for hair loss, there are also treatments available to address this issue.

How Has Howie’s Family and Close Friends Reacted to His Decision to Shave His Head?

How has Howie’s family and close friends reacted to his decision to shave his head? Well, let me tell you, they were initially shocked, but now they can’t stop praising his bold new look! It’s a total head-turner!

Conclusion

Howie Mandel’s bold bald move has left fans buzzing! The decision to shave his head was not only a personal style evolution, but also a confidence boost for the beloved comedian. Amidst concerns about hair loss and the influence of COVID-19, Mandel embraced his new look with gusto.

And let’s not forget the public’s reaction and support, which has been overwhelmingly positive. Howie’s head-turning transformation has truly captivated audiences, making him the talk of the town.

So, why did he shave his head? The answer is clear: Mandel’s fearless choice has made him a true trendsetter in the entertainment industry.

Lucy, with her knack for weaving words into compelling narratives, is a cherished member of our content team. Her journey into the world of content creation began with a love for storytelling, nurtured during evenings spent around campfires and family gatherings. These tales, filled with emotion and life lessons, left an indelible mark on her young mind, propelling her into the realm of writing.

-

Guides and Tutorials3 months ago

Guides and Tutorials3 months agoHow to Shave Head at Home

-

Community and Stories2 months ago

Community and Stories2 months agoWhy Did Britney Shave Her Head

-

Guides and Tutorials3 months ago

Guides and Tutorials3 months agoHow to Shave Half Your Head at Home

-

Community and Stories2 months ago

Community and Stories2 months agoWhy Did Daph Shave Her Head

-

Community and Stories3 months ago

Community and Stories3 months agoWhy Did Amanda Geise Shave Head

-

Community and Stories2 months ago

Community and Stories2 months agoWhy Did Pat Shave His Head

-

Community and Stories2 months ago

Community and Stories2 months agoWhy Did Bloodynine Shave His Head

-

Community and Stories3 weeks ago

Community and Stories3 weeks agoWhy Did Porter on Ghost Asylum Shave His Head